Enhanced Oil Recovery (EOR) represents a crucial set of techniques designed to squeeze more oil from depleted reservoirs. These methods, far from being simple afterthoughts, are sophisticated engineering feats that employ a variety of physical and chemical processes to coax out previously unreachable hydrocarbons. From injecting steam to manipulate viscosity to deploying carefully chosen chemicals to alter fluid interactions, EOR significantly extends the lifespan of oil fields and contributes substantially to global energy supplies.

Understanding these techniques is key to addressing both current energy demands and future sustainability concerns.

The core of EOR lies in understanding the complexities of reservoir geology and fluid dynamics. Different methods are tailored to specific reservoir characteristics, making reservoir characterization a critical first step. This involves detailed geological modeling and simulations to predict the effectiveness of different EOR approaches. The economic and environmental implications of each method are also carefully weighed, leading to a complex decision-making process that balances profitability with sustainability.

Enhanced Oil Recovery (EOR) Methods

Enhanced oil recovery (EOR) techniques are crucial for maximizing hydrocarbon production from mature oil reservoirs. These methods aim to improve the efficiency of oil extraction beyond the limits of primary and secondary recovery, which rely on natural reservoir pressure and water injection, respectively. A variety of techniques exist, each leveraging different physical mechanisms to mobilize and displace remaining oil.

Categorization of EOR Methods

EOR methods are broadly classified into three main categories based on their underlying mechanisms: thermal, miscible, and chemical. Thermal methods use heat to reduce oil viscosity, making it easier to flow. Miscible methods involve injecting fluids that mix completely with the oil, reducing interfacial tension and improving displacement efficiency. Chemical methods employ various chemicals to alter the properties of the oil or the reservoir rock, facilitating oil mobilization.

Thermal EOR Methods

Thermal EOR methods, including steam injection (Cyclic Steam Stimulation – CSS, Steam Flooding) and in-situ combustion, aim to heat the reservoir, reducing oil viscosity and improving its mobility. Steam injection, for instance, involves injecting steam into the reservoir to heat the oil and surrounding rock. This reduces the oil’s viscosity, making it flow more easily towards production wells. Cyclic Steam Stimulation is a less expensive, but less efficient method, involving repeated cycles of steam injection and production.

In-situ combustion involves burning a portion of the oil in the reservoir to generate heat, which reduces the viscosity of the remaining oil. Advantages include improved oil recovery in heavy oil reservoirs. Limitations include high energy consumption and potential for reservoir damage.

Enhanced Oil Recovery (EOR) techniques are crucial for maximizing oil extraction from depleted reservoirs. The cost-effectiveness of these methods is vital, much like considering the expense of designing a new home; finding out how much does it cost to use online AI home design software can help illustrate the importance of upfront planning. Ultimately, both EOR projects and home building require careful budget management for successful outcomes.

Miscible EOR Methods

Miscible displacement involves injecting fluids that completely mix with the oil, eliminating the interfacial tension between the oil and the displacing fluid. This allows for more efficient displacement of the oil towards production wells. Common miscible agents include hydrocarbons such as propane, butane, and carbon dioxide (CO2). CO2 injection is particularly attractive due to its availability and environmental benefits (carbon sequestration).

Advantages include high recovery efficiency in certain reservoir types. Limitations include high costs associated with procuring and injecting miscible fluids, as well as potential for reservoir damage if not carefully managed.

Chemical EOR Methods

Chemical EOR methods use various chemicals to improve oil recovery. Polymer flooding involves injecting polymers to increase the viscosity of the injected water, improving sweep efficiency and reducing water channeling. Surfactant flooding utilizes surfactants to reduce the interfacial tension between oil and water, improving oil mobilization and displacement. Alkaline flooding employs alkaline chemicals to alter the wettability of the reservoir rock, making it more oil-wet, and improving oil recovery.

Advantages include increased oil recovery in various reservoir types. Limitations include the high cost of chemicals, potential for chemical degradation, and the need for careful reservoir characterization to optimize chemical selection and injection strategies.

Enhanced Oil Recovery (EOR) techniques are crucial for maximizing oil extraction. Think about the complex optimization involved; it’s similar to designing a highly efficient home, like those created with AI powered home design software that integrates with smart home tech , where every element works together seamlessly. Ultimately, both EOR and smart home design rely on sophisticated data analysis and predictive modeling to achieve optimal results.

Comparison of EOR Methods

The effectiveness of different EOR methods varies significantly depending on reservoir characteristics, such as oil viscosity, reservoir temperature, and permeability. For instance, steam injection is highly effective in heavy oil reservoirs, while CO2 injection is more suitable for lighter oil reservoirs. Polymer flooding can be effective in reservoirs with high permeability, while surfactant flooding is more effective in reservoirs with low permeability.

| EOR Method | Capital Costs | Operational Costs | Environmental Impacts |

|---|---|---|---|

| Steam Injection | High (due to infrastructure requirements) | High (energy intensive) | High greenhouse gas emissions (if steam is generated using fossil fuels) |

| CO2 Injection | Moderate to High (depending on CO2 source and infrastructure) | Moderate (CO2 handling and injection) | Moderate (CO2 leakage potential, but can contribute to carbon sequestration) |

| Polymer Flooding | Low to Moderate (relatively simpler infrastructure) | Moderate (polymer costs and injection) | Low (generally less environmentally impactful than thermal methods) |

Reservoir Characterization for EOR

Successful Enhanced Oil Recovery (EOR) projects hinge on a thorough understanding of the reservoir’s properties. Accurate characterization allows engineers to select the most appropriate EOR method and predict its effectiveness, ultimately maximizing oil production and minimizing costs. This involves integrating diverse geological and geophysical data to create a detailed 3D model of the reservoir.Reservoir properties significantly impacting EOR method selection and success include porosity, permeability, fluid saturation, and reservoir pressure.

Porosity, representing the pore space within the rock, determines the amount of oil that can be stored. Permeability, measuring the ease with which fluids can flow through the rock, dictates the rate at which oil can be displaced. Fluid saturation describes the proportions of oil, water, and gas within the pore spaces, influencing the efficiency of different EOR techniques.

Finally, reservoir pressure drives the flow of fluids and impacts the effectiveness of pressure-based EOR methods. Variations in these properties, especially across heterogeneous formations, can significantly influence the overall success of an EOR project.

Geological Modeling and Simulation in EOR Optimization

Geological modeling uses data from various sources to create a three-dimensional representation of the reservoir. This model includes information on the reservoir’s geometry, rock properties, and fluid distribution. Simulation software then uses this model to predict the behavior of the reservoir under different EOR scenarios. This allows engineers to test various strategies, optimize injection parameters (e.g., injection rate, well placement), and evaluate the potential for enhanced oil recovery before implementation.

For example, a model might predict that injecting a surfactant solution into a specific area of the reservoir would yield a higher oil recovery than injecting it elsewhere, guiding well placement decisions. The simulations also allow for the evaluation of the impact of reservoir heterogeneity on the effectiveness of the EOR process.

Challenges in Characterizing Heterogeneous Reservoirs for EOR

Heterogeneous reservoirs, characterized by significant variations in rock properties and fluid distribution across the reservoir, present significant challenges to accurate characterization. The complexities arising from these variations make it difficult to create a truly representative model. Data acquisition in such formations is often sparse and uneven, leading to uncertainties in the model. Furthermore, the upscaling of properties from the core scale to the reservoir scale, necessary for numerical simulation, can introduce significant errors, potentially leading to inaccurate predictions of EOR performance.

This uncertainty underscores the need for advanced data integration techniques and sophisticated modeling workflows to minimize the risks associated with EOR projects in heterogeneous reservoirs. One real-world example involves the challenges faced in characterizing fractured shale reservoirs, where the complex fracture network significantly impacts fluid flow and makes accurate modeling exceptionally difficult.

Data Acquisition Methods for Reservoir Characterization in EOR Projects

Understanding the reservoir’s properties requires a comprehensive data acquisition strategy. Different techniques provide complementary information, building a more complete picture.

- Seismic Surveys: Provide large-scale images of the subsurface, revealing the structural framework and identifying potential reservoir boundaries.

- Well Logging: Involves deploying sensors down boreholes to measure various parameters such as porosity, permeability, and fluid saturation in-situ.

- Core Analysis: Involves extracting rock samples from boreholes for laboratory analysis to determine detailed petrophysical properties.

- Production Data Analysis: Analyzing historical production data provides insights into reservoir behavior and fluid properties.

- Pressure Transient Testing: Involves manipulating reservoir pressure to determine permeability and other reservoir properties.

Chemical EOR Techniques

Chemical Enhanced Oil Recovery (EOR) methods leverage the properties of specific chemicals to improve oil displacement efficiency in reservoirs. These techniques aim to alter the interfacial tension between oil and water, improve the mobility of the displacing fluid, or modify the wettability of the reservoir rock, ultimately leading to increased oil recovery. The three primary chemical EOR techniques are polymer flooding, surfactant flooding, and alkaline flooding.

Polymer Flooding Mechanisms

Polymer flooding employs water-soluble polymers to increase the viscosity of the injected water. This increased viscosity improves the sweep efficiency of the injected fluid, reducing the tendency for the water to bypass the oil and improving contact between the injected water and the oil. The chemical interaction involves the polymer molecules expanding and entangling in the water, creating a more viscous solution that displaces oil more effectively.

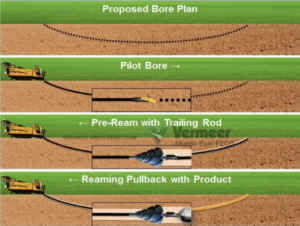

Enhanced Oil Recovery (EOR) techniques are crucial for maximizing oil extraction from mature fields. A key aspect often overlooked is the initial drilling process; the efficiency and precision of the initial wells, as you can see from this drilling resource Drilling , directly impacts the success of subsequent EOR methods. Ultimately, optimizing both drilling and EOR strategies is vital for long-term profitability.

The choice of polymer depends on the reservoir temperature, salinity, and other conditions. High molecular weight polymers are often preferred for their high viscosity, but they may also be more susceptible to degradation in the reservoir.

Surfactant Flooding Mechanisms

Surfactant flooding utilizes surface-active agents to reduce the interfacial tension between oil and water. This significantly reduces the capillary forces holding the oil in the pore spaces of the reservoir rock, making it easier to displace. The chemical interaction involves the surfactant molecules adsorbing at the oil-water interface, reducing the energy required to break the oil droplets apart and mobilize them.

The effectiveness of surfactant flooding depends on selecting a surfactant that is compatible with the reservoir fluids and rock, and on designing an appropriate injection strategy to ensure uniform distribution of the surfactant throughout the reservoir. The selection often involves testing various surfactants to determine their effectiveness in reducing interfacial tension under reservoir conditions.

Alkaline Flooding Mechanisms, Enhanced Oil Recovery (EOR)

Alkaline flooding uses alkaline chemicals, such as sodium hydroxide (NaOH) or sodium carbonate (Na2CO3), to alter the wettability of the reservoir rock and reduce interfacial tension. The chemical interaction involves the alkaline solution reacting with the acidic components in the crude oil and the reservoir rock, changing the surface charge and making the rock more water-wet. This improved water-wettability allows for better oil displacement.

Furthermore, the alkaline solution can also in-situ generate surfactants, further reducing interfacial tension. The effectiveness of alkaline flooding is highly dependent on the reservoir rock mineralogy and the nature of the crude oil.

Successful Applications of Chemical EOR

Numerous successful chemical EOR projects have been implemented worldwide. For example, polymer flooding has been effectively used in sandstone reservoirs in North America and Europe to improve sweep efficiency and increase oil recovery. Surfactant flooding has shown significant success in several Californian oil fields, overcoming challenges associated with highly heterogeneous reservoirs and complex fluid compositions. Alkaline flooding has been applied in various reservoirs, demonstrating success in specific cases where the reservoir characteristics and crude oil properties are favorable.

Challenges overcome include optimizing chemical formulations for specific reservoir conditions, designing efficient injection strategies to minimize chemical loss, and implementing effective monitoring techniques to track the progress of the flood.

Design Considerations for Chemical EOR Projects

Successful chemical EOR projects require careful planning and execution. Chemical selection involves considering factors such as reservoir temperature, salinity, pH, and the chemical compatibility with the reservoir fluids and rock. Injection strategies must ensure uniform distribution of the chemicals throughout the reservoir, minimizing bypass and channeling. This often involves optimizing injection rates, well placement, and the use of various injection patterns.

Monitoring techniques are crucial for tracking the progress of the chemical flood and adjusting the injection strategy as needed. These techniques typically involve regular pressure and production monitoring, as well as the analysis of produced fluids to determine the effectiveness of the chemical treatment.

Chemical Properties and Performance Characteristics

| Chemical | Chemical Formula | Key Properties | Performance Characteristics |

|---|---|---|---|

| Polyacrylamide | (C3H5NO)n | High molecular weight, water-soluble, high viscosity | Improved sweep efficiency, reduced water channeling |

| Sodium Dodecyl Sulfate (SDS) | CH3(CH2)11OSO3Na | Anionic surfactant, low interfacial tension | Reduced capillary pressure, improved oil mobilization |

| Sodium Hydroxide | NaOH | Strong alkali, alters wettability | Improved water-wettability, in-situ surfactant generation |

Thermal EOR Techniques

Source: technologystudent.com

Thermal Enhanced Oil Recovery (EOR) methods leverage the power of heat to improve oil extraction from reservoirs. By increasing the temperature of the reservoir, we reduce oil viscosity, making it flow more easily to the production wells. This approach is particularly effective in heavy oil reservoirs where the oil is too thick to be easily extracted using conventional methods.

Several thermal EOR techniques exist, each with its own advantages and disadvantages.

Enhanced Oil Recovery (EOR) techniques are crucial for maximizing oil extraction. Understanding the complexities of these methods is similar to grappling with the challenges in other fields using complex technologies, like exploring the limitations of using AI for home design online , where unforeseen issues can arise. Ultimately, both EOR and AI-driven design require careful consideration of limitations to achieve optimal results.

Steam Injection

Steam injection involves injecting high-pressure steam into the reservoir to heat the oil and reduce its viscosity. The heat transfer occurs primarily through conduction and convection. Conduction transfers heat through direct contact between the steam and the surrounding rock and oil, while convection involves the movement of heated fluids, transferring heat throughout the reservoir. The efficiency of steam injection depends on factors such as steam quality, injection rate, and reservoir properties.

Effective steam injection requires careful reservoir characterization to optimize injection strategies and minimize steam losses.

Enhanced Oil Recovery (EOR) techniques are crucial for maximizing oil extraction. Choosing the right method involves complex modeling, much like choosing a home design platform; you need to carefully consider your options before committing. If you’re looking for a visual comparison of different approaches, check out this helpful resource on comparing different AI powered home design platforms online – it’s surprisingly analogous to the decision-making process in EOR.

Ultimately, successful EOR depends on a well-informed strategy.

In-Situ Combustion

In-situ combustion, also known as fireflooding, involves burning a portion of the oil in the reservoir to generate heat in-situ. This method uses air or oxygen injection to sustain the combustion front, which propagates through the reservoir, heating the oil ahead of it. The heat transfer mechanisms include conduction, convection, and radiation. Radiation plays a more significant role in in-situ combustion compared to steam injection, as the combustion process generates significant radiant heat.

Successful in-situ combustion requires careful control of the combustion front to maintain efficient heat generation and avoid excessive heat loss.

Cyclic Steam Stimulation

Cyclic steam stimulation (CSS) is a less intensive thermal EOR method compared to continuous steam injection. It involves injecting steam into a well for a period of time, allowing it to heat the surrounding oil, and then producing the heated oil. This cycle is repeated several times to enhance oil recovery. The primary heat transfer mechanism is conduction and convection, similar to steam injection, but on a smaller scale and with shorter contact times.

Enhanced Oil Recovery (EOR) techniques are crucial for maximizing oil production from mature fields. A significant portion of these operations takes place in onshore locations, often involving the expertise of companies specializing in Onshore Drilling to access and maintain these wells. The efficiency of onshore drilling directly impacts the overall success of EOR projects, ultimately determining the final yield of oil extracted.

CSS is often used in reservoirs with relatively low permeability where continuous steam injection may be less efficient.

Equipment and Infrastructure for Thermal EOR

Implementing thermal EOR methods requires significant infrastructure and specialized equipment. This includes:

- Steam generators: These are large boilers that produce high-pressure steam for injection.

- Injection and production wells: Wells are drilled and equipped with downhole tools for steam injection and oil production.

- Surface facilities: This includes pipelines, pumps, separators, and other equipment for handling steam and produced fluids.

- Monitoring systems: Sensors and instrumentation are used to monitor pressure, temperature, and fluid flow rates within the reservoir.

- Water treatment facilities: Water is often treated to remove impurities before being used for steam generation.

The scale and complexity of these facilities vary depending on the size and characteristics of the reservoir and the specific thermal EOR method employed.

Energy Efficiency and Environmental Impact

Steam injection generally has a lower energy efficiency compared to in-situ combustion, as a significant portion of the injected steam energy is lost to the surrounding formations. In-situ combustion, while more energy-efficient in terms of oil produced per unit of energy input, presents greater environmental concerns due to the combustion process. In-situ combustion produces greenhouse gases (CO2, NOx, SOx) and requires careful management to minimize environmental impact.

Steam injection primarily consumes energy and water resources, and the disposal of produced water can pose environmental challenges. The choice between these methods depends on a careful trade-off between energy efficiency, environmental impact, and reservoir characteristics. For example, in reservoirs with thick, heavy oil and high permeability, in-situ combustion might be preferred despite the environmental concerns. Conversely, in reservoirs with lower permeability, steam injection might be a more viable option, despite the lower energy efficiency.

Steam Injection EOR Project Design and Implementation

The following flowchart Artikels the steps involved in designing and implementing a steam injection EOR project:

Miscible EOR Techniques

Miscible Enhanced Oil Recovery (EOR) methods leverage the complete mixing of injected fluids with the resident oil in the reservoir, significantly improving oil displacement efficiency compared to immiscible techniques. This complete mixing reduces interfacial tension to near zero, eliminating capillary pressure and improving sweep efficiency. Two primary approaches dominate miscible EOR: CO2 injection and hydrocarbon miscible flooding.

Types of Miscible Displacement Processes

Miscible displacement relies on the creation of a miscible bank – a region where the injected fluid and reservoir oil are completely miscible. This is achieved either by injecting a solvent that is naturally miscible with the reservoir oil or by altering the properties of the injected fluid and/or the reservoir oil to achieve miscibility. The two main categories are CO2 injection and hydrocarbon miscible flooding.

CO2 injection is often favored due to its relatively low cost and readily available supply, particularly in reservoirs containing lighter oils. Hydrocarbon miscible flooding, conversely, uses liquefied petroleum gas (LPG) or other hydrocarbons, offering advantages in reservoirs with heavier oils, though at a higher cost. The choice depends heavily on reservoir characteristics and oil properties.

Factors Affecting Miscible Displacement Efficiency

Several factors influence the effectiveness of miscible displacement. Crucially, fluid properties such as viscosity, density, and interfacial tension play vital roles. The injected fluid’s viscosity should be appropriately matched to the reservoir oil’s viscosity to ensure efficient displacement. A significant density difference between the injected fluid and the oil can lead to gravitational segregation, hindering the process.

Enhanced Oil Recovery (EOR) techniques are crucial for maximizing oil extraction. Thinking about optimizing resource extraction reminds me of optimizing design processes; check out these top rated AI home design websites with easy user interfaces for a glimpse into efficient design. Just as AI streamlines home design, innovative EOR methods aim to streamline the oil extraction process, ultimately boosting overall production.

Furthermore, reservoir characteristics such as permeability, porosity, and heterogeneity significantly impact the sweep efficiency. High permeability pathways can channel the injected fluid, leaving significant oil behind in less permeable zones. Heterogeneities in reservoir properties further complicate the displacement process, potentially reducing the overall recovery. Accurate reservoir characterization is paramount for effective miscible EOR design.

Potential Risks and Challenges of Miscible EOR

While miscible EOR offers significant potential for enhanced oil recovery, several risks and challenges exist. CO2 leakage is a major environmental concern, requiring careful monitoring and mitigation strategies to prevent greenhouse gas emissions. Geological instability, including induced seismicity, can occur due to pressure changes in the reservoir during injection. Furthermore, the cost of CO2 sourcing, compression, transportation, and injection can be substantial.

The selection of an appropriate injection strategy and the careful monitoring of the reservoir are crucial to minimize these risks and maximize the efficiency of the process. Accurate prediction of reservoir behavior under these pressure and compositional changes is critical.

Design of a Miscible Displacement Process

Let’s consider a hypothetical reservoir model: a 1 km² reservoir with an average thickness of 20 meters, porosity of 20%, and permeability of 200 mD. The reservoir oil has an initial oil saturation of 70% and a viscosity of 20 cp. We will employ CO2 injection, assuming it achieves miscibility with the reservoir oil under the anticipated pressure and temperature conditions.

The injection pattern will be a five-spot pattern, with injection wells located at the corners of a square and a production well at the center. Fluid properties will be carefully matched to ensure optimal displacement efficiency. The predicted outcome, based on reservoir simulation, is an additional 20% oil recovery beyond primary production. This projection considers factors like CO2 injectivity, reservoir heterogeneity, and the potential for gravity override.

The success of this project hinges on accurate reservoir modeling, careful injection rate management, and rigorous monitoring to ensure safe and efficient CO2 injection. A similar approach, substituting CO2 with LPG, could be employed for heavier oil reservoirs, adjusting parameters accordingly.

Enhanced Oil Recovery (EOR) techniques are crucial for maximizing oil production from existing wells. Successfully implementing EOR often relies heavily on the initial data gathered during the Oil Exploration phase, as understanding the reservoir’s characteristics is paramount to choosing the right EOR method. Therefore, thorough exploration is a key precursor to effective EOR strategies.

Economic and Environmental Aspects of EOR

Enhanced Oil Recovery (EOR) methods offer a crucial pathway to accessing remaining oil reserves, but their implementation involves significant economic and environmental considerations. A comprehensive assessment must balance the potential for increased oil production with the associated costs and environmental impacts to ensure responsible and sustainable resource management. This section explores the economic feasibility of various EOR techniques and details their environmental consequences, offering a comparative analysis and potential mitigation strategies.

Economic Feasibility of EOR Methods

The economic viability of any EOR project hinges on a complex interplay of factors. Capital costs, encompassing the initial investment in equipment, infrastructure, and project setup, can be substantial, varying significantly depending on the chosen EOR method and reservoir characteristics. Operating costs, including chemical procurement, energy consumption (especially for thermal methods), and ongoing maintenance, represent a continuous expense throughout the project’s lifespan.

Crucially, the profitability of an EOR project is directly tied to the prevailing oil price. High oil prices increase the likelihood of a positive return on investment, while low prices can render even the most efficient EOR methods uneconomical. For example, a thermal EOR project might be profitable at $80/barrel oil but unsustainable at $40/barrel. Detailed financial modeling, incorporating realistic cost projections and oil price forecasts, is essential for determining the economic feasibility of each EOR method on a case-by-case basis.

Environmental Impacts of EOR Techniques

EOR methods, while essential for maximizing oil recovery, carry potential environmental consequences. Greenhouse gas emissions, primarily carbon dioxide (CO2), are a significant concern, particularly with thermal EOR techniques like steam injection. The energy required for steam generation contributes to a larger carbon footprint. Furthermore, the production and transportation of chemicals used in chemical EOR methods can also generate emissions.

Water usage is another critical environmental aspect, as many EOR techniques, including waterflooding and thermal methods, require substantial volumes of water. This can strain local water resources and raise concerns about potential water pollution from produced water containing dissolved salts, chemicals, and hydrocarbons. The disposal or treatment of this produced water is a major logistical and environmental challenge.

Finally, potential risks of soil and groundwater contamination exist, depending on the specific EOR technique and the effectiveness of containment measures.

Comparison of Environmental Footprints and Mitigation Strategies

Comparing the environmental footprints of different EOR methods requires a holistic approach, considering various factors such as greenhouse gas emissions, water consumption, and potential for contamination. Generally, chemical EOR methods tend to have a lower carbon footprint compared to thermal methods, but their chemical usage introduces other environmental risks. Miscible flooding methods fall somewhere in between, depending on the specific solvent used.

Mitigation strategies are crucial for minimizing negative impacts. These include optimizing injection rates and strategies to reduce energy consumption and greenhouse gas emissions in thermal methods, employing environmentally friendly chemicals and efficient water management practices in chemical EOR, and implementing robust monitoring and remediation plans to prevent and mitigate potential contamination. Carbon capture and storage (CCS) technologies can also play a significant role in reducing the carbon footprint of EOR operations, although the economic viability and scalability of CCS remain challenges.

Potential Environmental Regulations and Permitting Requirements

The implementation of EOR projects is subject to a range of environmental regulations and permitting requirements, which vary depending on the location and specific EOR method employed.

- Air quality permits for managing greenhouse gas emissions and other air pollutants.

- Water discharge permits to regulate the quality and quantity of produced water released into surface or subsurface waters.

- Waste management permits for the disposal of hazardous materials and produced water.

- Permits related to injection and disposal wells to ensure safe and environmentally sound operations.

- Compliance with regulations concerning the use and handling of chemicals.

- Environmental impact assessments (EIAs) are often required to evaluate the potential environmental consequences of the project.

- Regular monitoring and reporting requirements to track environmental performance and ensure compliance with permits and regulations.

Failure to comply with these regulations can lead to significant penalties, project delays, and reputational damage. Thorough understanding and adherence to applicable regulations are essential for the successful and responsible implementation of EOR projects.

Wrap-Up: Enhanced Oil Recovery (EOR)

In conclusion, Enhanced Oil Recovery offers a multifaceted approach to maximizing oil production from existing reservoirs. While each method presents its own advantages and challenges, ranging from capital costs and operational complexities to environmental considerations, the overall impact of EOR on global energy security is undeniable. Continued innovation and refinement of these techniques, coupled with responsible environmental management, will be crucial in ensuring a sustainable and efficient future for oil extraction.

Question Bank

What are the main risks associated with EOR?

Risks vary depending on the specific EOR method. Common concerns include potential for induced seismicity (especially with high-pressure injection), groundwater contamination, greenhouse gas emissions (particularly with thermal methods), and the cost and complexity of implementation.

How long does an EOR project typically take?

The timeframe is highly variable, depending on the reservoir characteristics, the chosen EOR method, and the project’s scale. It can range from several months for smaller projects to several years for large-scale operations.

Is EOR used for all types of oil reservoirs?

No, the suitability of EOR depends heavily on the reservoir’s properties, including its permeability, porosity, temperature, pressure, and oil viscosity. Some reservoirs are simply not economically viable for EOR.

What is the future of EOR technology?

The future likely involves further advancements in reservoir modeling and simulation, the development of more efficient and environmentally friendly chemicals, and the integration of data analytics and artificial intelligence to optimize EOR processes. Research into carbon capture and storage techniques related to EOR is also gaining traction.