Downstream processes, the final stages of a supply chain or production line, are critical for delivering goods and services to consumers. Understanding the complexities of downstream operations, from oil refining to marketing and distribution, is crucial for navigating the challenges and opportunities they present. This exploration delves into the multifaceted world of downstream activities, examining their impact across various industries and offering insights into effective management strategies.

We’ll investigate how upstream disruptions ripple through downstream operations, exploring mitigation techniques and risk management strategies. We’ll also analyze the environmental and economic consequences of downstream activities, considering the role of government policies and technological advancements. Finally, we’ll examine successful marketing and distribution models, highlighting best practices for optimizing efficiency and reaching target markets.

Downstream Effects in Supply Chains

Downstream businesses, those closer to the end consumer, are significantly impacted by disruptions occurring further up the supply chain. These disruptions, whether caused by natural disasters, labor disputes, or geopolitical instability, can create a ripple effect that significantly affects production, delivery timelines, and ultimately, profitability. Understanding these downstream effects and implementing proactive risk mitigation strategies is crucial for business continuity.

Cascading Impact of Upstream Disruptions

Disruptions at the upstream end of a supply chain, such as a supplier factory fire or a port closure, immediately affect the availability of raw materials or intermediate goods. This shortage then cascades down the chain, impacting downstream manufacturers who may face production halts due to a lack of necessary components. These manufacturers, in turn, may delay shipments to distributors and retailers, leading to stockouts and unmet consumer demand.

The impact can extend to the consumer level, causing price increases and potentially damaging brand reputation. For example, a semiconductor shortage in 2021 caused significant delays in the production of automobiles and electronics globally.

Downstream data speeds are crucial for a smooth online experience, especially when streaming or downloading. To get the best bang for your buck, you’ll want to check out a comparison of different providers; a good resource for this is komparasi paket internet indosat dengan provider lain to help you decide. Ultimately, understanding your downstream needs is key to selecting the right internet plan.

Mitigation Strategies for Downstream Businesses

Downstream businesses employ several strategies to mitigate risks stemming from upstream vulnerabilities. Diversifying suppliers is a common approach, reducing reliance on a single source and spreading risk across multiple vendors. Building strong relationships with key suppliers allows for better communication and collaboration during disruptions, enabling early warning systems and contingency planning. Holding safety stock of critical components acts as a buffer against short-term disruptions, allowing for continued production even when supply is temporarily interrupted.

Finally, investing in robust supply chain visibility tools enables real-time monitoring of inventory levels and potential disruptions, allowing for proactive adjustments.

Comparison of Downstream Effects from Different Disruptions

Natural disasters, like earthquakes or hurricanes, often cause widespread and immediate disruptions, impacting multiple points in the supply chain simultaneously. The downstream effects are typically characterized by significant delays, shortages, and price increases across a broad range of products. Labor strikes, on the other hand, tend to be more localized and focused on specific industries or regions. While the impact can be severe for businesses directly affected, the downstream consequences may be less widespread.

For instance, a strike at a major port might severely disrupt the flow of goods for specific industries reliant on that port, but its impact on other sectors might be minimal.

Risk Management Strategy for Downstream Businesses

A comprehensive risk management strategy for a downstream business should incorporate several key elements. This includes identifying potential upstream vulnerabilities, assessing the likelihood and impact of various disruptions, developing contingency plans to address these scenarios, and establishing clear communication channels with suppliers and customers. Regular supply chain audits and stress testing can help identify weaknesses and improve resilience. The strategy should also incorporate elements of supplier diversification, safety stock management, and advanced supply chain visibility technologies.

Finally, a robust crisis management plan is essential for effectively responding to and recovering from disruptions.

Interdependence of Upstream and Downstream Activities in the Automotive Industry

| Upstream Activity | Downstream Activity | Interdependence | Potential Disruption & Impact |

|---|---|---|---|

| Raw Material Extraction (Iron Ore, Rubber) | Vehicle Assembly | Raw materials are essential for manufacturing vehicle components. | Mining strike: Reduced steel production, impacting vehicle production. |

| Component Manufacturing (Engines, Tires) | Dealership Sales | Component availability determines vehicle production and availability for sale. | Factory fire: Delays in vehicle production, reduced inventory at dealerships. |

| Logistics & Transportation | After-Sales Service | Efficient delivery of vehicles and parts is crucial for sales and service. | Port congestion: Delays in vehicle delivery, impacting sales and service parts availability. |

| Research & Development (New Technologies) | Customer Satisfaction | Innovation drives customer demand and future vehicle designs. | Lack of R&D investment: Reduced innovation, potentially impacting long-term market competitiveness. |

Downstream Oil and Gas Processing

The downstream sector of the oil and gas industry encompasses the transformation of crude oil and natural gas into usable products. This complex process involves several stages, each with its own environmental considerations and technological advancements. Understanding these stages is crucial for evaluating the industry’s overall impact and exploring avenues for improvement.

Stages of Downstream Oil and Gas Processing

Downstream processing begins with the transportation of crude oil from extraction sites to refineries. This is followed by a series of refining processes to separate crude oil into various components. These components are then further processed to create a wide range of products, including gasoline, diesel, jet fuel, heating oil, liquefied petroleum gas (LPG), and petrochemicals. Finally, these products are distributed to consumers through a network of pipelines, tankers, and trucks.

Environmental Considerations in Downstream Processing

Each stage of downstream processing presents unique environmental challenges. Crude oil transportation can lead to spills and water pollution. Refining processes release greenhouse gases like carbon dioxide, methane, and sulfur oxides, contributing to air pollution and climate change. Furthermore, wastewater from refineries can contain hazardous substances, necessitating careful treatment before disposal. The production and distribution of refined products also contribute to air and water pollution through emissions and potential spills.

Minimizing these impacts requires stringent environmental regulations, technological advancements, and responsible operational practices.

Downstream processes often rely heavily on reliable data access. For students, this means finding affordable internet plans, like those offered by Indosat with their great deals on large data allowances; check out this link for more info: paket internet indosat murah dan kuota besar untuk pelajar. Ultimately, a strong downstream connection is crucial for smooth data processing and efficient work.

Technological Advancements in Downstream Oil and Gas Operations

The downstream sector is constantly evolving with technological advancements aimed at improving efficiency, reducing environmental impact, and enhancing product quality. These include improved refinery designs for enhanced energy efficiency and reduced emissions, advanced catalysts for cleaner and more efficient refining processes, and sophisticated monitoring systems for real-time process optimization and environmental control. Furthermore, the development of biofuels and other alternative fuels is reducing reliance on traditional fossil fuels.

The integration of artificial intelligence and machine learning is also improving process control, predictive maintenance, and overall operational efficiency.

Comparison of Refining Techniques

Different refining techniques are employed to process crude oil into various products. These include fractional distillation, which separates crude oil into different boiling point fractions; catalytic cracking, which breaks down larger hydrocarbon molecules into smaller, more valuable ones; and hydrocracking, which uses hydrogen to break down larger molecules under high pressure and temperature. The specific techniques used depend on the properties of the crude oil and the desired product slate.

For instance, heavier crude oils may require more extensive processing involving catalytic cracking and hydrocracking to produce higher yields of gasoline and other lighter products. The selection of refining techniques is a crucial factor influencing both product quality and environmental impact.

Crude Oil Refining Process Flowchart

Imagine a flowchart with these stages:

1. Crude Oil Arrival

Crude oil arrives at the refinery via pipeline or tanker.

2. Pre-heating and Desalting

The crude oil is pre-heated and impurities like salt are removed.

3. Fractional Distillation

The heated crude oil enters a distillation column where it separates into various fractions based on boiling points (e.g., naphtha, kerosene, gas oil).

4. Conversion Processes

Fractions undergo further processing like catalytic cracking, hydrocracking, and reforming to improve quality and yield desired products.

5. Treatment Processes

Products undergo treatment to remove impurities like sulfur and improve stability.

6. Blending

Different fractions are blended to create final products like gasoline, diesel, and jet fuel.

7. Storage and Distribution

Understanding downstream data flow is crucial for efficient network management. If you’re experiencing unexpectedly high data usage, check out this helpful guide on penyebab pulsa indosat cepat habis dan solusinya to troubleshoot potential issues. Addressing these issues can significantly improve your downstream performance and reduce wasted data.

Finished products are stored in tanks and distributed to consumers via pipelines, tankers, and trucks.

Downstream Consequences of Policy Decisions

Government policies significantly impact downstream industries, influencing their economic viability, social standing, and overall market dynamics. These policies, ranging from taxation and regulation to trade agreements and subsidies, can have both intended and unintended consequences, often with far-reaching effects. Understanding these impacts is crucial for effective policymaking and sustainable industry growth.

Downstream data speeds are crucial for a smooth online experience, especially when streaming or downloading. To get the best bang for your buck, you’ll want to check out a comparison of different providers; a good resource for this is komparasi paket internet indosat dengan provider lain to help you decide. Ultimately, understanding your downstream needs is key to selecting the right internet plan.

Economic Implications of Government Policies on Downstream Industries

Government policies directly influence the profitability and competitiveness of downstream businesses. For instance, carbon taxes aimed at reducing emissions can increase production costs for energy-intensive downstream sectors like manufacturing or transportation. Conversely, subsidies for renewable energy sources can boost the economic viability of downstream industries involved in renewable energy production and distribution. These policies can also affect investment decisions; a stable and predictable policy environment encourages long-term investments, while frequent policy changes can lead to uncertainty and hinder investment.

A clear example is the fluctuating price of carbon credits, which makes long-term planning difficult for businesses involved in carbon offsetting. This uncertainty can lead to reduced investment and slower growth.

Unintended Consequences of Policy Changes on Downstream Businesses

Policy changes, even those with good intentions, can have unintended negative consequences for downstream businesses. Consider a hypothetical scenario: a government introduces a stringent new regulation requiring all food packaging to be fully biodegradable within six months. While aiming for environmental sustainability, this could disproportionately impact smaller food processing companies lacking the resources to quickly adapt to the new standard.

This could lead to business closures, job losses, and potentially even shortages of certain food products. Similarly, a sudden increase in minimum wage, while beneficial for workers, could force some downstream businesses with tight profit margins to reduce staff or raise prices, potentially impacting consumers.

Social Impact of Regulatory Changes in the Food Processing Sector

Regulatory changes in the food processing sector can have significant social impacts. For example, stricter regulations on food safety and labeling, while improving public health, might increase the cost of food, disproportionately affecting low-income households. Conversely, regulations promoting fair labor practices in the agricultural sector, a key upstream component of food processing, could improve working conditions and reduce exploitation, leading to positive social outcomes.

The implementation of stricter hygiene standards in meat processing plants, for example, while increasing costs, significantly reduces the risk of foodborne illnesses, improving public health and reducing healthcare costs in the long run. This demonstrates a complex interplay between economic and social impacts.

Influence of Lobbying Efforts on Downstream Market Dynamics

Lobbying efforts by industry groups and stakeholders significantly influence downstream market dynamics. Powerful industry lobbies can successfully advocate for policies that benefit their members, such as tax breaks or relaxed environmental regulations. This can lead to an uneven playing field, favoring larger corporations over smaller businesses. Conversely, consumer advocacy groups can lobby for policies that protect consumer interests, such as stricter product safety regulations or clearer labeling requirements.

The outcome of these lobbying efforts shapes the regulatory landscape and directly impacts the competitiveness and profitability of downstream businesses.

Policy Recommendations to Support the Growth of the Renewable Energy Sector

Government support is crucial for the growth of the renewable energy sector. A comprehensive strategy is needed to overcome existing challenges and foster sustainable development.

- Tax incentives and subsidies: Offer tax credits and subsidies to incentivize investment in renewable energy technologies and infrastructure.

- Streamlined permitting processes: Simplify and expedite the permitting process for renewable energy projects to reduce delays and costs.

- Investment in research and development: Increase funding for research and development to drive innovation and improve the efficiency and cost-effectiveness of renewable energy technologies.

- Smart grid development: Invest in modernizing the electricity grid to better integrate renewable energy sources and improve grid stability.

- Skills development and training: Support education and training programs to develop a skilled workforce capable of installing, maintaining, and operating renewable energy systems.

Downstream Marketing and Distribution

Effective downstream marketing and distribution are crucial for the success of any business, regardless of industry. This section explores the complexities of managing these processes, highlighting challenges, effective strategies, and best practices for optimization. We will examine the various distribution channels and analyze a case study illustrating the impact of a well-executed (or poorly executed) marketing campaign.

Challenges in Managing Downstream Distribution Networks

Managing downstream distribution networks presents numerous challenges. These include geographical dispersion of customers, the need for efficient inventory management to avoid stockouts or overstocking, managing transportation costs and complexities, ensuring product quality and integrity throughout the supply chain, and adapting to changing customer demands and market conditions. Furthermore, businesses must contend with logistical hurdles such as unpredictable weather, traffic congestion, and potential disruptions to transportation networks.

Effective risk management and contingency planning are essential to mitigate these challenges.

Effective Marketing Strategies for Downstream Products

Successful downstream marketing strategies often leverage a multi-channel approach, combining digital marketing with traditional methods. For example, a company selling consumer electronics might utilize targeted online advertising (e.g., Google Ads, social media campaigns) alongside in-store promotions and print advertising in relevant magazines. Building strong brand awareness and customer loyalty is key, often achieved through consistent messaging, exceptional customer service, and loyalty programs.

Data-driven marketing, using analytics to track campaign performance and refine strategies, is becoming increasingly important. Understanding customer demographics and preferences through market research is also crucial for tailoring marketing messages effectively.

Downstream data speeds are crucial for a smooth online experience, especially when streaming or downloading. To get the best bang for your buck, you’ll want to check out a comparison of different providers; a good resource for this is komparasi paket internet indosat dengan provider lain to help you decide. Ultimately, understanding your downstream needs is key to selecting the right internet plan.

Comparison of Distribution Channels in the Food and Beverage Industry

The food and beverage industry offers a clear example of diverse downstream distribution channels. Direct-to-consumer sales (e.g., online ordering, company-owned stores) allow for greater control over the brand experience but require significant investment in infrastructure and logistics. Wholesale distribution involves selling products to retailers who then sell them to consumers, offering wider reach but potentially sacrificing some control over pricing and marketing.

Downstream data speeds are crucial for a smooth online experience, especially when streaming or downloading. To get the best bang for your buck, you’ll want to check out a comparison of different providers; a good resource for this is komparasi paket internet indosat dengan provider lain to help you decide. Ultimately, understanding your downstream needs is key to selecting the right internet plan.

Franchise models offer a balance between control and expansion, while third-party logistics providers can handle transportation and warehousing, freeing up internal resources. The choice of distribution channel depends on factors such as product type, target market, budget, and company goals.

Best Practices for Optimizing Downstream Logistics and Inventory Management

Optimizing downstream logistics and inventory management involves implementing several best practices. This includes utilizing advanced technologies such as warehouse management systems (WMS) and transportation management systems (TMS) to improve efficiency and track shipments. Implementing just-in-time inventory management minimizes storage costs and reduces waste. Strategic warehouse location selection minimizes transportation distances and times. Collaboration with logistics providers and strong supplier relationships are essential for smooth operations.

Regularly reviewing and refining logistics processes through data analysis is also crucial for continuous improvement.

Case Study: The Launch of “Sunshine Snacks” Energy Bars

Sunshine Snacks launched a new line of energy bars targeting health-conscious consumers. Their marketing campaign heavily utilized social media influencers, creating engaging content showcasing the bars’ benefits and taste. They also partnered with fitness studios and gyms for product sampling and promotions. A bar graph visually represented the campaign’s success. The x-axis showed months (launch month to month six), and the y-axis showed sales figures.

The graph showed a steady increase in sales over the six months, peaking in month four, followed by a slight plateau. A pie chart alongside showed the breakdown of sales channels: 40% online sales, 30% retail stores, and 30% fitness studios. The campaign was deemed a success, exceeding initial sales projections by 25% within the first six months.

The key to success was a well-defined target audience, a compelling brand message, and a multi-channel marketing approach that effectively reached the target demographic.

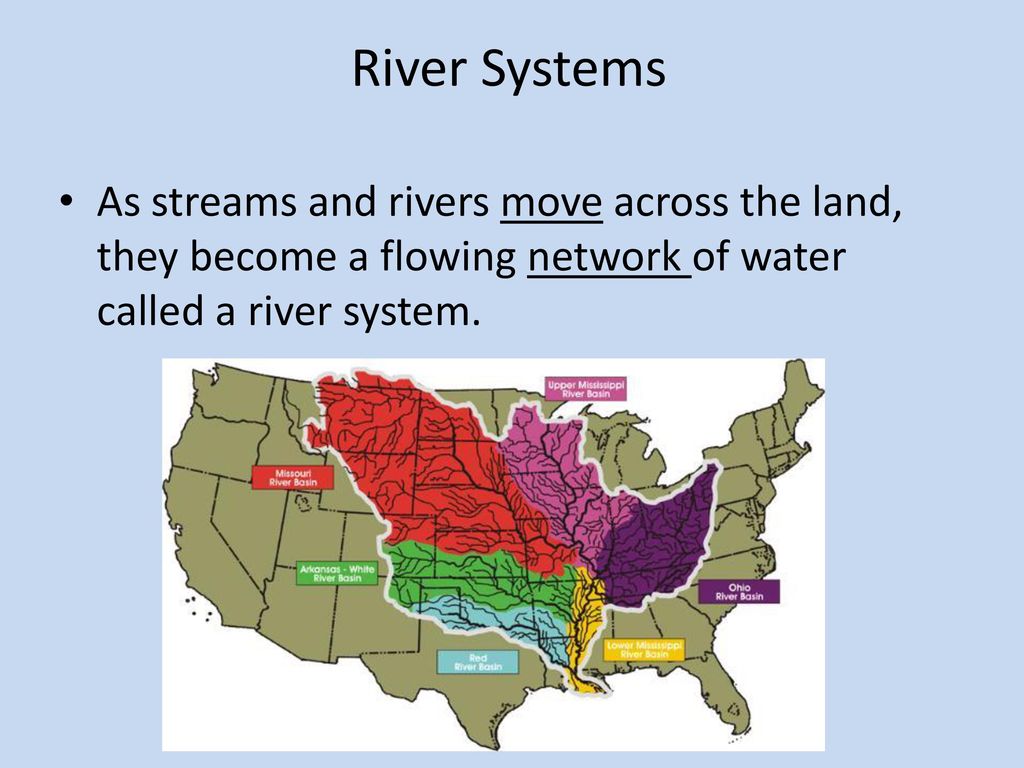

Downstream Water Management

Source: slideplayer.com

Downstream industries, encompassing sectors like manufacturing, energy production, and agriculture, significantly impact water resources. Their water usage often leads to environmental consequences, necessitating sustainable management practices. This section explores the environmental effects of downstream water use, effective efficiency improvements, relevant regulatory frameworks, pollution costs, and a sample sustainable water management plan.

Environmental Impact of Water Usage in Downstream Industries

The environmental impact of water usage in downstream industries is multifaceted. Large volumes of water are often withdrawn from rivers and aquifers for industrial processes, leading to decreased water availability for ecosystems and other users. This can cause habitat loss, disrupt aquatic life cycles, and even lead to the depletion of groundwater resources. Furthermore, the discharge of wastewater containing pollutants, such as heavy metals, chemicals, and suspended solids, can severely contaminate water bodies, harming aquatic organisms and potentially affecting human health through contaminated drinking water sources.

The thermal pollution from industrial discharge can also alter aquatic ecosystems by affecting the temperature sensitivity of aquatic species. For example, power plants using water for cooling can significantly raise the temperature of receiving water bodies, harming aquatic life.

Methods for Improving Water Efficiency in Downstream Operations

Improving water efficiency in downstream operations is crucial for environmental sustainability and cost savings. Several methods can be employed. These include implementing water recycling and reuse systems, where wastewater is treated and reused in industrial processes, minimizing water consumption through process optimization and technological advancements such as high-efficiency equipment, and employing precision irrigation techniques in agriculture to reduce water waste.

Leak detection and repair programs are also essential for minimizing water loss. Investing in water-efficient technologies, such as membrane filtration systems for wastewater treatment, can significantly reduce water consumption and pollution. Adopting drought-resistant crops and employing rainwater harvesting techniques can further enhance water efficiency in agricultural downstream operations.

Downstream data speeds are crucial for a smooth online experience, especially when streaming or downloading. To get the best bang for your buck, you’ll want to check out a comparison of different providers; a good resource for this is komparasi paket internet indosat dengan provider lain to help you decide. Ultimately, understanding your downstream needs is key to selecting the right internet plan.

Regulatory Framework Governing Water Usage in the Oil and Gas Sector

The oil and gas sector faces stringent regulations regarding water usage. The specific regulations vary by location but generally involve obtaining permits for water withdrawals and discharges, adhering to water quality standards for wastewater effluents, and implementing environmental impact assessments for new projects. For example, in the United States, the Environmental Protection Agency (EPA) sets national water quality standards, while individual states manage water allocation and permitting.

These regulations often mandate regular monitoring of water usage and discharge quality, along with reporting requirements. Non-compliance can result in significant penalties, including fines and operational shutdowns. The regulatory framework aims to minimize the environmental impact of oil and gas operations on water resources, promoting responsible water management practices.

Costs Associated with Water Pollution and Remediation in Downstream Processes

Water pollution from downstream processes incurs substantial costs. These include the direct costs of remediation efforts, such as cleaning up contaminated sites, treating polluted water, and installing pollution control technologies. Indirect costs include the loss of ecosystem services, such as decreased fisheries productivity and reduced recreational opportunities. Furthermore, there are potential health costs associated with waterborne diseases resulting from contaminated water.

Legal liabilities and penalties for non-compliance with environmental regulations can also significantly increase the overall cost. For instance, the Deepwater Horizon oil spill resulted in billions of dollars in cleanup costs, environmental damage, and legal settlements.

Sustainable Water Management Plan for the Oil and Gas Sector

This plan focuses on minimizing water usage and pollution in oil and gas extraction and processing.

Goal: To achieve a 20% reduction in water consumption and a 30% reduction in wastewater discharge within five years.

Downstream processes often rely on readily available data. For example, efficiently managing your internet usage involves understanding how to quickly purchase data packages. Check out this guide on how to buy Indosat internet packages via their app: bagaimana cara membeli paket internet indosat lewat aplikasi to streamline your downstream activities and avoid unexpected data overages. This helps ensure your downstream operations run smoothly.

Strategies: Implementing water recycling and reuse systems in refineries and processing plants; optimizing water usage in hydraulic fracturing operations through advanced technologies; investing in advanced wastewater treatment technologies to meet or exceed regulatory discharge limits; conducting regular water quality monitoring and reporting; and implementing a comprehensive leak detection and repair program.

Compliance: Adhering to all applicable federal, state, and local regulations regarding water usage and discharge; obtaining necessary permits for water withdrawals and discharges; and conducting regular environmental audits to ensure compliance.

Monitoring and Evaluation: Tracking water consumption and wastewater discharge volumes regularly; conducting periodic water quality assessments; and evaluating the effectiveness of implemented strategies to ensure the plan’s goals are met.

Contingency Planning: Developing a plan to address unexpected events, such as equipment failures or spills, to minimize environmental impact and ensure rapid response.

Epilogue

From the cascading effects of upstream disruptions to the intricacies of downstream marketing, this examination reveals the interconnectedness of various stages within supply chains and production processes. By understanding the challenges and opportunities inherent in downstream operations, businesses can develop robust strategies for mitigating risks, optimizing efficiency, and achieving sustainable growth. The future of downstream management hinges on adapting to evolving technologies, environmental regulations, and market demands, ensuring a smooth flow of goods and services to consumers worldwide.

Query Resolution

What are some common downstream challenges in the food industry?

Common challenges include perishable goods, fluctuating consumer demand, and maintaining cold chain integrity during transportation and storage.

How does technology impact downstream logistics?

Technology, such as GPS tracking, automated warehousing, and predictive analytics, significantly improves efficiency, reduces costs, and enhances transparency in downstream logistics.

What are the ethical considerations in downstream operations?

Ethical considerations include fair labor practices, sustainable sourcing, responsible waste management, and transparency throughout the supply chain.

How can a downstream business improve its sustainability?

Improving sustainability involves implementing water conservation techniques, reducing carbon emissions, minimizing waste, and sourcing sustainable materials.